Recharging Sustainable Mobility

Dr. Mohammad Sedigh Toulabi’s work stands at the forefront of redefining how electric machines are designed, built and integrated into modern transportation.

In the heart of Michigan’s automotive corridor, a new research laboratory spearheads a hub of innovation. As the automotive industry demands better, faster and greener electrified powertrains, the Power Electronics and Energy Conversion (PEEC) Lab, located in the School of Engineering and Computer Science (SECS) Research and Innovation Center, is advancing tools and research capabilities to re-define the electric motors and drives that will propel the next generation of lightweight and heavy-duty electric vehicles.

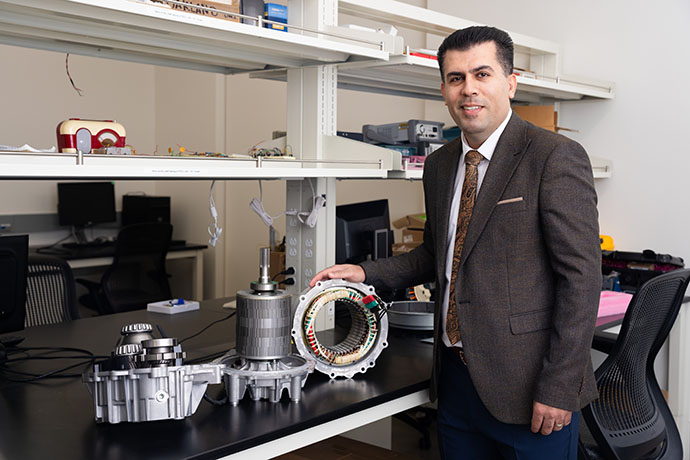

Mohammad Sedigh Toulabi, Ph.D., assistant professor of electrical and computer engineering, leads the PEEC Lab with a vision to make transportation electrification more robust, efficient and environmentally sustainable, transforming advanced power engineering theory into practical solutions.

For Dr. Toulabi, the PEEC Lab’s establishment was a natural step in a research journey shaped by innovation and collaboration. Over the years, he has created advanced mathematical and simulation models for a range of rare-earth-free (REF) electric motors, refining their geometries to achieve greater power density and efficiency. Through prototyping and rigorous experimentation, he successfully validated the performance of permanent magnet-assisted synchronous reluctance motors (PMaSynRMs), synchronous reluctance motors (SynRMs), switched reluctance motors (SRMs) and induction motors. This research, conducted in the past with collaborators from China, Italy and Canada, as well as North American OEMs and Tier 1 suppliers, now continues and evolves through new projects at the PEEC Lab .

“Traditional high-performance electric motor designs rely heavily on rare-earth magnets. These elements are expensive, environmentally demanding to produce, and often sourced from unstable global markets. At the PEEC Lab, our focus is on developing REF electric motor drive systems that operate without these costly and sensitive materials. Reducing dependence on rare-earth elements can make electric vehicles more sustainable, affordable and accessible, while strengthening the nation’s energy independence and supply-chain security,” Dr. Toulabi explains.

First conceptualized and prototyped during Dr. Toulabi's postdoctoral work at the University of Manitoba, Canada, the high-performance REF electric machines were brought to Oakland University through a partnership with this institution. Since their arrival, the PEEC team –– which now includes graduate students Ahmad Almomani and Yazan Al-Geizawi, and undergraduate student Khanh Phan –– has implemented design and manufacturing refinements as well as developed a custom model of the machines.

“We model, prototype and test REF electric machines for the next generation of efficient drive systems. With the use of artificial intelligence (AI) in both design and control, we managed to elevate how these machines operate. For instance, we improved high-fidelity parameter estimation for field-oriented control,” says Ahmad Almomani, who is pursuing a Ph.D. in electrical and computer engineering. He credits this experience with strengthening his ability to contribute to the future of intelligent and sustainable electric drive technologies.

|

|---|

| OU graduate students, Ahmad Almomani and Yazan Al-Geizawi, work at the PEEC Lab to model, prototype and test REF electric machines for the next generation of efficient drive systems. |

The REF machines now serve as the cornerstone of ongoing experimental research at PEEC Lab.

“The combination of REF motors and testing equipment allows the PEEC Lab team to validate REF designs at a scale and precision rivaling top research centers, connecting material science, advanced modeling and full-scale vehicle testing in a single collaborative environment,” says Daniel Aloi, Ph.D., SECS director of research.

A defining feature of Dr. Toulabi’s research is the seamless integration of theory, simulation and experimentation. At the PEEC Lab, students, faculty and industry collaborators translate digital designs into physical prototypes, while testing and refining them in real time.

“Since our team transforms the computer models of REF electric machines into working prototypes and analyzes their multiphysics characteristics (e.g. electrical, mechanical and thermal behaviors), I had an opportunity to apply electric machines coursework concepts such as torque production, magnetic flux behavior and core loss analysis to interpret simulation results and refine motor designs. Seeing how these principles translate into real-time testing and performance validation has been an exciting bridge between classroom theory and advanced engineering practice,” shares Khanh Phan, an electrical engineering major.

As the PEEC Lab continues to expand its research and collaborations, its work stands at the forefront of redefining how electric machines are designed, built and integrated into modern transportation. Through advanced modeling, AI-driven control and experimental validation, Dr. Toulabi and his team are recharging sustainable mobility.

To learn more about Dr. Toulabi’s research or potential collaboration opportunities, contact him at [email protected].

|

|---|

| PEEC Lab Director, Dr. Toulabi, presenting the stator, rotor and gearbox for a 150 kW electric motor used in an electric vehicle propulsion system. |

December 19, 2025

December 19, 2025

By Arina Bokas

By Arina Bokas