Beyond Clean Energy

By integrating mechanical engineering, materials science and catalytic chemistry, Dr. Francisco Cepeda is helping reshape the way the science thinks about hydrogen and carbon.

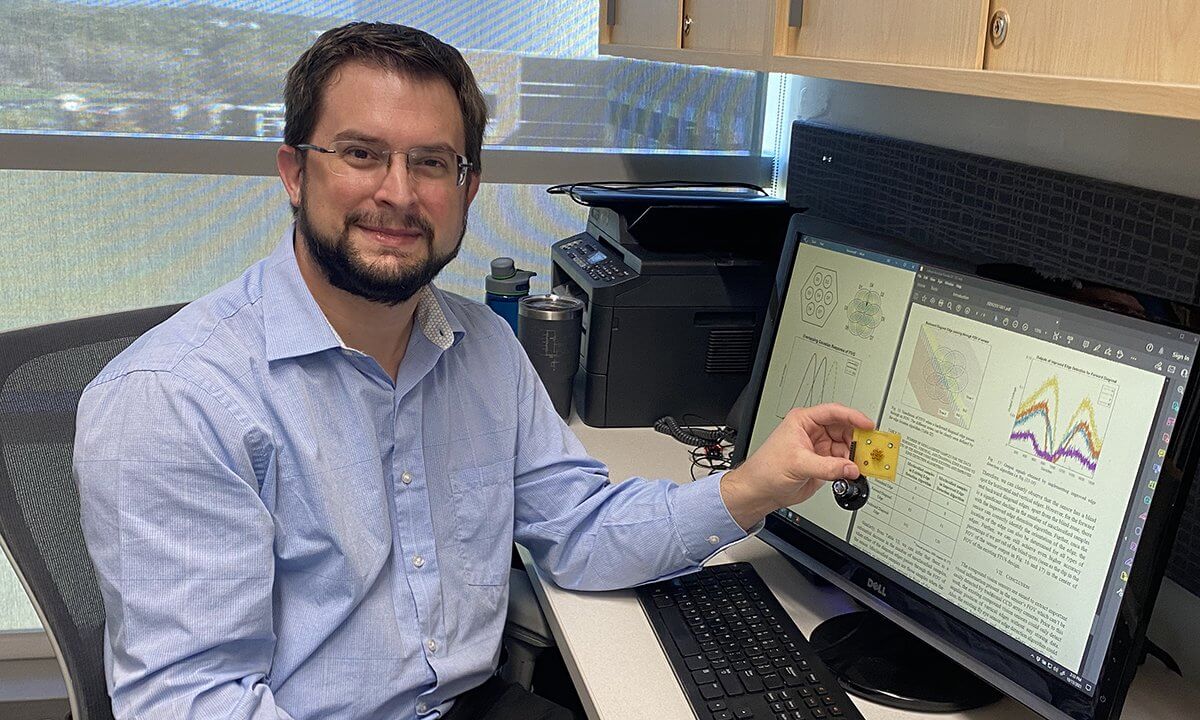

In the E-Carbon Laboratory, adjutant to the School of Engineering and Computer Science Energy Lab, Francisco Cepeda, Ph.D., assistant professor of mechanical engineering, is probing one of industry’s most pressing questions: how can hydrogen be produced cleanly, efficiently and sustainably? The answer, he believes, lies in the subtleties of carbon formation during methane pyrolysis.

“Hydrogen is often called the fuel of the future –– a clean fuel critical for countless industrial processes, from fertilizer production to refining and energy generation. Yet, most of today’s hydrogen is produced through steam methane reforming (SMR), a technique that emits significant amounts of carbon dioxide into the atmosphere. As the global demand for hydrogen surges (it is expected to exceed 600 million tons annually by mid-century), the environmental cost of these methods can no longer be ignored,” Dr. Cepeda explains the need for a more sustainable alternative.

At the intersection of energy science and advanced materials, Dr. Cepeda’s research centers on carbon formation during methane pyrolysis –– a process that splits methane into hydrogen gas and solid carbon, rather than carbon dioxide (CO₂), eliminating the need for costly CO₂ capture or storage.

There are also additional benefits to this process. Frequently carbon is perceived as a nuisance, a buildup that reduces efficiency or fouls reactors. However, Dr. Cepeda sees it as an opportunity to create something of value. The solid carbon can be valorized into such high-demand materials as graphitic carbon, nanostructures and composites for aerospace or energy applications. Thus, understanding what kind of carbon forms during methane pyrolysis –– and how it can be controlled –– paves the way to optimizing both hydrogen production efficiency and carbon material properties.

Dr. Cepeda’s research integrates advanced modeling with detailed materials characterization, coupling computational fluid dynamics (CFD) with high-resolution microscopy and spectroscopy. This multi-scale approach allows him to link reactor-scale flow dynamics to the nanoscale morphology of carbon deposits, a novel step toward predictive, controllable carbon engineering.

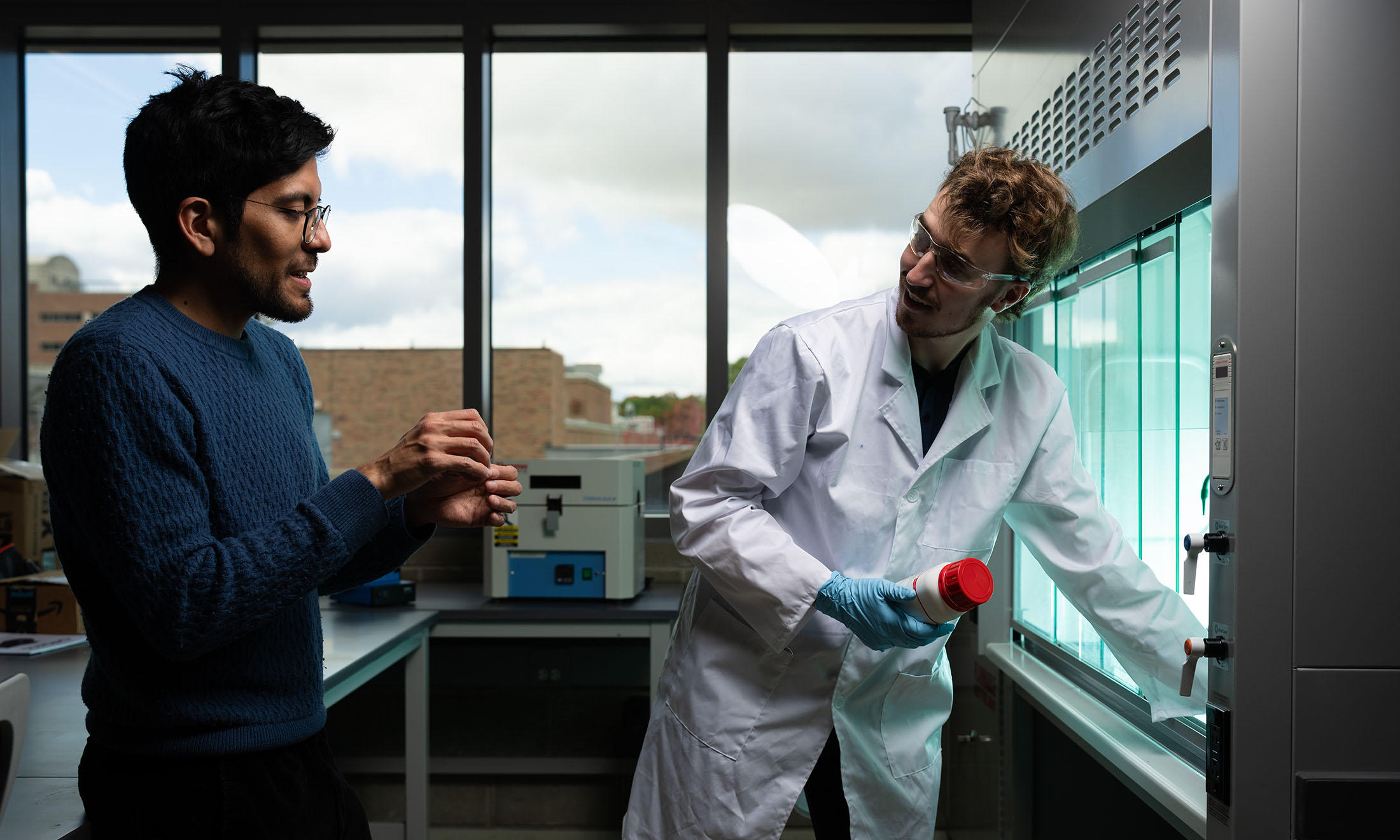

“We design and operate small, high-temperature reactors where methane or other carbon-rich gases flow through and decompose into hydrogen and solid carbon. To study how that carbon can be transformed into graphitic materials at lower temperatures, we add special metal- and carbon-based catalysts, heat the samples and use electron microscopes and spectroscopy to observe how the carbon’s internal structure and morphology change. We also utilize models that integrate computational fluid dynamics with detailed carbon formation frameworks to simulate how temperature, flow and catalyst placement affect the process. By comparing the simulations with what we observe under the microscope, we can learn how to control the type of carbon we produce,” says Aiden Martin, a B.S./M.S. mechanical engineering student, who works at Dr. Cepeda’s laboratory.

“We’re essentially bridging the physics of large-scale reactors with the chemistry of atomic-scale processes,” adds Dr. Cepeda. “By understanding how variables like temperature and gas flow influence carbon structure, we can fine-tune the process to achieve both efficiency and quality: producing clean hydrogen and a valuable carbon product.”

Dr. Cepeda’s prior research has already demonstrated how gas-phase dynamics and material synthesis conditions influence carbon growth and hydrogen yield. As Michigan is positioning itself as a hub for the emerging hydrogen economy, Dr. Cepeda’s upcoming project proposals target not only cleaner manufacturing but also new methods for carbon valorization. This approach could reduce industrial waste, lower production costs and open high-tech manufacturing opportunities in the state.

|

|---|

| Dr. Cepeda’s upcoming project proposals target not only cleaner manufacturing but also new methods for carbon valorization. |

The URC Fellowship project, “Process–Structure Relationships in Methane Pyrolysis for Hydrogen and Carbon Production,” aims to develop a new multi-scale model that is capable of predicting how carbon deposits evolve on reactor surfaces. Meanwhile, the Michigan Space Grant Consortium (MSGC) Seed project, “Toward Graphitic Carbon from Methane Pyrolysis: Process Control and Nanostructural Evolution,” aspires to explore how to harness process conditions to deliberately produce graphitizing carbon –– a material needed in aerospace applications and high-energy storage devices. Together, these efforts lead to reactor systems that don’t just avoid emissions but also create value.

In an age defined by the pursuit of sustainability, Dr. Cepeda’s research shows that innovation is not just in learning to control reactions. Rather, it occurs when science understands them deeply enough to transform their products. By integrating mechanical engineering, materials science and catalytic chemistry, the researcher is helping to reshape the way that science thinks about both hydrogen and carbon. His vision extends beyond cleaner fuels –– it’s about designing intelligent systems where every process gives rise to new materials and new possibilities.

For more information about Dr. Cepeda’s research, visit his website: https://sites.google.com/oakland.edu/e-carbon-lab/home

December 19, 2025

December 19, 2025

By Arina Bokas

By Arina Bokas